PEX Plumbing

PEX Tube

PEX tube is a kind ofPEX-a, which in preparation , Peroxide method is used in a different way.

method is used in a different way.

These technique is a new method which in dynamical processes of incorporation and mixing of solids and liquids, tube formation and Finally heating , Performed by highly advanced Reliable equipment.

AccordinglyPEX tube of Pars Ethylene Kish Co is in higher rank than other similar products and popular brands in the world in terms of features.

PEX tubes and fittings applications :

♦ Hot and cold water plumbing systems in new buildings or Under Renovation buildings.

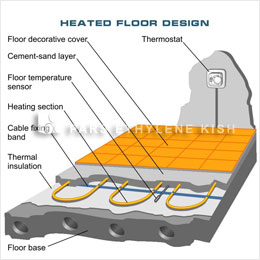

♦ Floor heating in residential buildings, commercial offices and hospitals

♦ Plumbing, heating and air conditioning systems, such as radiators, fan coils and ...

♦ Ice melting systems in parking lots, sidewalks and streets

♦ Floor heating in greenhouses and Sports ground such as Gridiron or golf

♦ Water and fire fighting systems in residential buildings, service, office and industrial sections.

These tubes can easily be replaced with hard sort pipes. Use Manifold in the PEX plumbing system Balance the outlet pressure, reduce the waiting time for hot water, reduce the length of pipes and number of fittings, Increase the speed of installation and Will result significant savings in energy consumption.

The Excellence of pex tubes:

♦ Flexibility and more strength than other pipes

♦ Greater thermal resistance

♦ Complete return to the initial state due to the strong shape memory

♦ Resistance to frost

♦ Greater resistance against abrasion and corrosion

♦ Quick Installation, simple and reliable

♦ Corrosion resistant, durable permanent

♦ Reduction of Current and future costs

♦ Maintain efficiency till building remains

superiority of Pars Ethylene Kish Co floor heating system:

♦ Temperature uniformity and thermal comfort

♦ Significant savings in energy consumption (about 30%)

♦ Staying clean walls, And the absence of soot and dust in the interior of the building

♦ More space and freedom in interior design and decoration

♦ Better Appearance

♦ No need for cumbersome and costly repairs

Dimension and tube Series table according to standards DIN 16893:2003, ISO 15875 - 2: 2003

Pipe Series | Mean OutSide

Diameter | Nominal

OutSide

Diameter | Nominal

size

DN/OD |

S 3,2 | S 4 | S 5 | S 6,3 |

Wall thicknesses

Emin and En | dem.max | dem.min | dn | | | | | |

2.2 | 1.8 | 1.5 | 1.3 | 16.3 | 16.0 | 16 | 16 |

2.8 | 2.3 | 1.9 | 1.5 | 20.3 | 20.0 | 20 | 20 |

3.5 | 2.8 | 2.3 | 1.9 | 25.3 | 25.0 | 25 | 25 |

4.4 | 3.6 | 2.9 | 2.4 | 32.3 | 32.0 | 32 | 32 |

5.5 | 4.5 | 3.7 | 3.0 | 40.4 | 40.0 | 40 | 40 |

6.9 | 5.6 | 4.6 | 3.7 | 50.5 | 50.0 | 50 | 50 |

8.6 | 7.1 | 5.8 | 4.7 | 63.6 | 63.0 | 63 | 63 |