Application of polyethylene pipes in landfills

Landfills are dynamic environments which are in stable state of change. Optimal and successful management and operation of landfills need skill, technology, materials and modern tools and using experienced experts. Pipes in landfills are very important because they transfer wastewaters and toxic gases. Pipes used in the landfills should be resistant against chemical reactions and can maintain their integrity for long-term.

HDPE has extraordinary resistance against destructive and corrosive chemicals, including soil and moisture (lifespan above 100 years). Polyethylene pipes ( HDPE Pipe )are ideal pipes for certain soil environments, like landfills.

Today, sanitary landfills needs materials and aggregates with stable and long-term performance. Pars Ethylene Kish provides complete range of polyethylene pipes (single-wall pipe, double-wall pipe, drainpipe, grooved pipes) for using in the sanitary landfills.

Major applications of Pars Ethylene Kish products in landfills

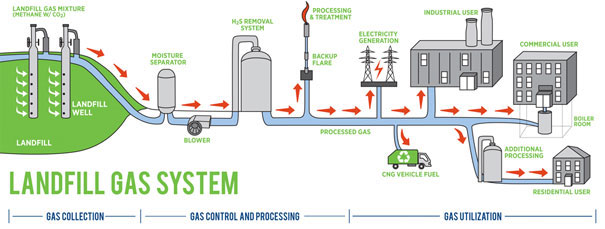

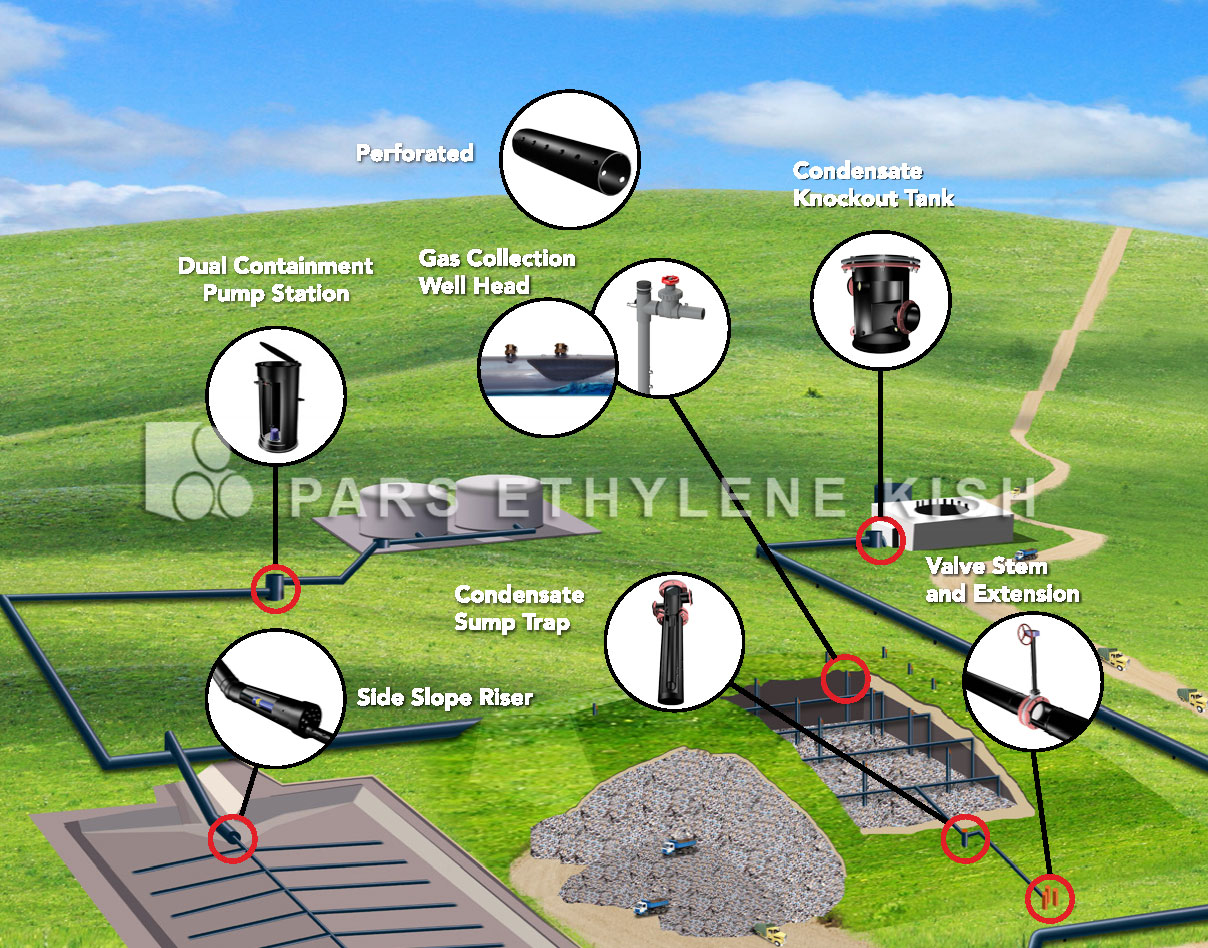

Gas extraction and transmission

Methane gas forms as a natural product of waste decomposition in landfills. Gas extraction and collection has helped reducing harmful effects of this gas on the environment and provide ground for transferring it to small and local refineries for treatment and recovery and optimal use of methane gas.

Wastewater transmission

Landfills have active environments. Through natural processes like precipitation, soil pressure and decomposition, landfills produce a liquid waste called wastewater. Wastewaters often include dangerous and toxic materials which need correct management.

Pars Ethylene Kish produces products to help management of wastewaters, including single-wall polyethylene pipes, grooved pipes and also fittings and electro-fusion.

Some of the mostly used Pars Ethylene Kish products

Pars Ethylene Kish produces widespread range of polyethylene pipes, fittings and manholes with the best material and modern German machineries which meet the needs of engineering plans and projects.

Today, Pars Ethylene Kish polyethylene piping systems have been used in the most firefighting systems' projects, water transmission pressure projects and urban and industrial sewage transmission systems and also natural gas transmission in the industrial and chemical environments, telecommunication projects and cable covering.

New generation of Pars Ethylene Kish corrugate pipes produce by using the advanced and modern production of double-wall corrugate polyethylene pipes' production line in the world. This production line is totally made in Germany and enjoys advanced German engineering.

Spiral polyethylene pipes can be used in cases when weight of soil exceeds the corrugate pipes threshold. Spiral polyethylene pipes can also be used in the liquid transmissions or air transmission canals on the surface or under the ground in low pressures.

Drainpipes of this company are only produced pipes in Iran which are made completely according to the Germany DIN 1187 standard. It has six holes in each row and their drain surface is better compared to other pipes.

Polyethylene hand holes have diverse applications like protective box of fittings, counter box, monitoring box in cable lines, visit box in water, oil and gas lines. Pars Ethylene Kish hand holes produce depending their application in different dimension, size and forms.

Polyethylene manhole is another product of Pars Ethylene Kish Company which is made of best raw materials and best design relative to similar samples. Regarding widespread application pf polymer products in different industries throughout the world, it can be a suitable alternative for concrete manholes and other manholes constructed with masonry aggregates.

Polyethylene pipelines in different projects need polyethylene fittings that these fittings will be different regarding type of project and application.