Advantages of Polyethylene: A Versatile and Durable Material

Introduction:

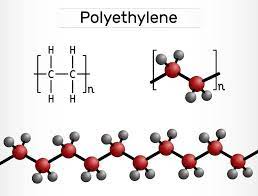

Polyethylene, a type of thermoplastic polymer, is widely used in various industries due to its numerous advantages. In this article, we will explore the remarkable benefits of polyethylene, ranging from its flexibility and impact resistance to its lightweight nature and ease of production. Additionally, we will delve into its recyclability, resistance to weather conditions and corrosion, chemical durability, odorlessness, material preservation capabilities, mechanical strength, electrical insulation, compatibility, and cost-effectiveness. Join us on this insightful journey as we uncover the many advantages of polyethylene.

1. Flexibility and Impact Resistance:

Polyethylene exhibits exceptional flexibility, making it suitable for applications that require a material capable of bending and stretching without breaking. Its high impact resistance allows it to withstand heavy impacts, making it an ideal choice for products that need to endure rough handling or potential accidents.

2. Lightweight Nature and Ease of Production:

One of the significant advantages of polyethylene is its lightweight nature. This property makes it desirable for applications where weight reduction is crucial, such as automotive components and packaging materials. Furthermore, polyethylene's ease of production allows for efficient manufacturing processes, resulting in cost savings and increased productivity.

3. Recyclability:

Polyethylene is highly recyclable, contributing to sustainable practices and environmental conservation. Through recycling processes, used polyethylene products can be transformed into new materials, reducing waste and minimizing the reliance on virgin resources. This eco-friendly aspect of polyethylene enhances its appeal in industries striving for sustainability.

4. Resistance to Weather Conditions and Corrosion:

Polyethylene exhibits excellent resistance to weather conditions, including sunlight, moisture, and temperature variations. This property makes it suitable for outdoor applications, such as construction materials, pipes, and agricultural products. Additionally, polyethylene's resistance to corrosion ensures its longevity in harsh environments, making it a reliable choice for infrastructure projects and chemical storage applications.

5. Chemical Durability:

Polyethylene demonstrates remarkable chemical resistance, making it compatible with a wide range of substances. It remains unaffected by many acids, bases, solvents, and other chemicals, ensuring the integrity and longevity of products made from polyethylene. This property positions polyethylene as a preferred material in industries such as chemical processing, pharmaceuticals, and food packaging.

6. Odorless and Antimicrobial Properties:

Polyethylene is odorless and does not emit unpleasant odors, distinguishing it from certain other plastic materials. Moreover, its dense structure prevents the growth of bacteria and microorganisms on its surface, making it inherently antimicrobial. These characteristics make polyethylene a suitable choice for applications where hygiene and cleanliness are paramount, such as medical equipment, food storage containers, and sanitary products.

7. Material Preservation Capabilities and Mechanical Strength:

Polyethylene's low permeability and resistance to moisture and gases make it an excellent material for preserving and protecting various substances. It acts as a barrier, preventing the entry of external elements that may affect the quality or integrity of the stored materials. Furthermore, polyethylene possesses impressive mechanical strength, enabling it to withstand pressure and heavy loads, making it suitable for demanding applications in construction, transportation, and manufacturing industries.

8. Electrical Insulation:

Polyethylene exhibits excellent electrical insulation properties, making it a preferred material in the electrical and electronics industry. Its ability to prevent the flow of electric current allows for safe and efficient utilization in electrical cables, wiring, and insulating materials.

9. Compatibility:

Polyethylene demonstrates good compatibility with other materials and chemicals. This attribute enhances its applicability in various industries, including chemical processing, medical, and food industries, where

compatibility between different components is essential for seamless operations and product quality.

10. Cost-effectiveness:

Polyethylene's cost-effectiveness is another significant advantage. Its availability, ease of production, and recyclability contribute to lower production costs, making it an economical choice for manufacturers. Additionally, its durability and longevity reduce maintenance and replacement expenses, further enhancing its cost-effectiveness over the long term.

Conclusion:

Polyethylene's diverse advantages have established it as a versatile and valuable material across numerous industries. Its flexibility, impact resistance, lightweight nature, ease of production, recyclability, weather resistance, chemical durability, odorlessness, material preservation capabilities, mechanical strength, electrical insulation, compatibility, and cost-effectiveness make it an optimal choice for a wide range of applications. With its remarkable properties and sustainable characteristics, polyethylene continues to drive innovation and contribute to a more efficient and environmentally conscious future.

Read more:

Advantages of Polyethylene Tanks

The Benefits of Polyethylene vs. Traditional Materials in Water and Wastewater Pipe Applications

Advantages of Polyethylene Underground Pipe

Polyethylene Pipe (PE pipe)

Polyethylene fittings

Polyethylene manhole

Polyethylene Pipe (PE pipe)

Polyethylene fittings