Multilayer Injection Molding Process for Polyethylene Pipe Production: Advantages and Applications

Polyethylene pipes produced using the multilayer injection molding process are one of the advanced and essential technologies in the pipe manufacturing industry. This process utilizes layers of polyethylene with distinct properties to create pipes with unique characteristics and superior performance. For instance, layers with enhanced resistance to pressure and impacts, resistance to corrosion, and UV protection can be incorporated into the pipes. This technology enables the production of pipes with extended service life and improved performance, enhancing the strength and durability of the pipes.

1. Introduction

Polyethylene pipes are widely used in various industries due to their outstanding features such as flexibility, corrosion resistance, and lightweight. With the continuous advancements in technology and material science, the methods for polyethylene pipe production have also improved, with new approaches aimed at producing pipes with diverse properties and applications. The multilayer injection molding process is one of these innovative methods that combines different layers of polyethylene within a mold to create pipes with unique and enhanced properties.

2. Multilayer Injection Molding Process in Polyethylene Pipe Production

The multilayer injection molding process involves using advanced injection molding machines to create layers of different polyethylene materials inside the pipe. These layers are chosen based on the specific needs and applications of the pipes, such as resistance to pressure, corrosion, and harmful radiation.

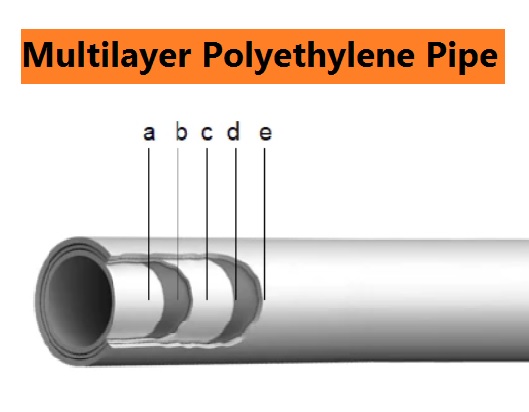

3. Types of Layers Used in Multilayer Injection Molding

In the multilayer injection molding process, various types of layers are utilized, each with its distinctive properties. These layers include resistance layers, corrosion-resistant layers, UV protection layers, and high-temperature resistant layers. Incorporating these layers in the production of polyethylene pipes enhances their resistance to different environmental conditions and extends their service life.

4. Applications of Multilayer Polyethylene Pipes

Multilayer polyethylene pipes find applications in a wide range of industries due to their exceptional properties. They are extensively used in the oil and gas industry, water and wastewater treatment, agriculture and irrigation systems, chemical industries, and power generation. The enhanced resistance and durability of these pipes make them a reliable and cost-effective choice for many industries.

5. Advantages and Capabilities of the Multilayer Injection Molding Process

The multilayer injection molding process offers several advantages over conventional methods of polyethylene pipe production. These advantages include increased resistance to pressure and impacts, enhanced corrosion resistance and protection against environmental factors, reduced unwanted heat transfer, longer service life, and improved overall performance. The utilization of this process results in pipes with superior quality and performance, making it an attractive option for various industries.

6. Conclusion

The multilayer injection molding process is an advanced technology in polyethylene pipe production, enabling the creation of pipes with diverse characteristics and improved performance. Its advantages, such as increased resistance to pressure and impacts, corrosion resistance, UV protection, and longer service life, contribute to the durability and reliability of polyethylene pipes. Given the extensive applications of these pipes in various industries, the adoption of the multilayer injection molding process can lead to significant improvements in the quality and performance of the pipes, making it an ideal choice for selecting suitable pipes for different industrial applications.

Read More: