Polyethylene Septic Tank

What is Septic Tank?

Septic Tank is a pre-treatment unit that reduces the amount of wastewater contaminated by 25-30%. Septic tanks are the simplest and most commonly used unit for sewage treatment, especially human sanitary sewage.

Septic tank is a reservoir in which sewage treatment is treated by processes such as sedimentation, flotation and biological treatment. Physical and biological processes are the main processes that cause sewage treatment in septic tank. These processes mainly include sedimentation, flotation and biological anaerobic processes, each of which reduces a portion of the burden of contamination.

Septic tanks are widely used in residential and villa units, residential and office complexes, construction workshops, manufacturing and industrial factories, hotels, restaurants, and recreational and sports complexes.

Application of Septic Tank

Septic tanks have expanded their application to various household, health and industrial sectors. Some of the main uses of septic tank are

-

Pre-treatment and purification of sanitary wastewater from residential units, commercial and office complexes, hotels and restaurants due to municipal laws and the Environmental Protection Agency

-

Removal of contaminated particles, fats and oils in sewage from restaurants and dining halls to prevent the rapid filling of wells and clogging of pipes due to accumulation of fat and coarse deposited particles

-

Balancing and pumping of sewage in sewage treatment systems

Polyethylene Septic tanks

The enormous benefits of polyethylene have increased the use of septic tanks to grow increasingly. Ease of operation and high performance are the main features of the polyethylene septic tanks .

-

High resistance to corrosion and inappropriate environmental conditions

-

Full sealing of septic tanks of polyethylene and the release of any contamination outside it

-

The wall is highly resistant to pressures from soil around the septic tanks of polyethylene

-

High speed construction, installation of septic tanks

-

The possibility of burial in the underground with the aim of transferring gravity of sewage to septic tank and preventing the occupation of useful spaces

-

Light weight and ease of carrying and installing

-

Possibility of septic tank displacement even a few years after the initial installation.

-

Ease of operation and discharge of sludge from septic tank due to visibility and sludge drainage.

-

Anti UV coating.

-

Complete and no odor isolation.

Septic tank components

-

Sewage Inlet System: Includes pipe and baffle (inlet).

-

Primary Tank Septic tank: which has the largest septic tank volume and typically accounts for 70-60% of the total septic tank volume in this section.

-

Separator wall: It prevents the introduction of sludge and fats and flotation oils into the drainage tank.

-

Drain tank: This reservoir contains about 30% of the total septic tank capacity, in which the wastewater is free of leachate and floatation.

-

Bio-Gas Outlet (Ventilation): Through this duct, the gases generated by the anaerobic treatment of sewage treatment, which is mainly methane, leave the septic tank.

-

Sewage Outlet System: Includes baffle and Septic Tank Outlet Tube.

.jpg)

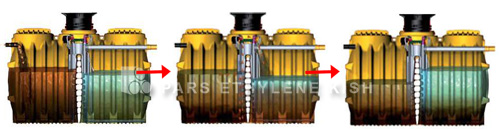

Operation of Septic Tank

The sewage enters the first section of the septic tank through the entrance pipe. This section, separated by a separating wall from the second part of the reservoir, contains a volume equivalent to two-thirds of the total septic tank volume. With the entry of sewage into this section, suspended matter and foreign particles move downward due to their weight and fall into the bottom of the reservoir. Oils and fats move upwards and float on the surface because they have a lower specific gravity than the sewage.

The accumulation of deposited materials in the reservoir floor creates a mass of sludge and microorganisms and bacteria multiply and grow. The biological reactions that occur during their propagation and growth cause the decomposed organic pollutants and sewage to be purified. These reactions also convert a significant amount of sludge to biogas and reduce the amount of sludge. The biogas produced, which is mainly methane, is extracted from the septic tank via the biogas exit pipe. In the next step, the first section, through the communication path embedded in the separator wall, enters the second part of the septic tank into the second section of the tank septic tank. In this section, very fine fats and oily particles that remain in the sewage float on the surface. Ultimately, the effluent is removed from the septic tank through the outlet pipe.

The sludge accumulated in the septic tank requires about one to two years to evacuate. It is better to drain, leaving a little bit of sludge in the tank's septic tank. Because this sludge contains microorganisms and bacteria that are effective in refining, and their full discharge causes a long time to reboot the biological septic tank.

Benefits of Septic Tanks

-

Sewage treatment will be simple and cost effective.

-

Cheap and affordable

-

Ease and speed at installation and inexpensive (due to the weight of the septic tank of the tank, which eliminates a lot of overhead costs)

-

Allows sewage treatment in remote areas without facilities.

-

With proper implementation and operation, septic tanks allow groundwater re-entry.

-

Lifespan for at least 50 years.

-

Low maintenance and repair costs

-

Without moving and electromechanical equipment

-

High strength of the wall and low occupied space due to the possibility of burial.

-

it can be installed at any depth according to the project.

-

High resistance to ultraviolet UV.

-

High chemical resistance against acids, basins, gases from sewage.

-

Soil corrosion resistance and acidic materials in the soil.

-

High flexibility for optimal use in rugged areas.

-

Ability to build them in the desired dimensions

-

Continuous treatment

-

Full and accurate sealing.

-

Healthy and well resistant.

-

Good resistance to fracture and cracks (against earthquake)

-

Suitable for wastewater treatment of small units

.jpg)

Septic Tank Price

Calculating the septic tank price is done according to its dimensions, specifications of the materials used and the material grades, and the diameter and weight of the tanks, and according to the standards of this product.

The septic tank price list as well as the price of septic tanks of polyethylene are calculated based on the price of raw material sales on the stock exchange, taking into account the cost of producing and delivering the factory door and based on the grades of raw materials in kilograms or on the basis of meters. The septic tile price table for polyethylene tanks (price list) is also followed by the above formula that was said.

Sewage septic tank

septic tank sewage is often used as a temporary waste disposal solution due to the importance of reducing pollution and organic wastewater. In this method, all sewage from the sewage system is sewed to the sewage septic tank . The interactions in the sewage septic tank include the initial refinement of sewage, which is the same sedimentation. Sewage septic tank can play a significant role in sewage treatment, by creating an efficient environment at the beginning of the sewage treatment line in the treatment plants, in addition to creating a stagnant and turning the flow into a slow stream.

Types of Septic Tanks

Types of septic tanks are usually divided into four general categories in terms of their reservoirs:

-

Septic tank of polyethylene

-

Two shells polyethylene septic tank

-

One shell polyethylene septic tank

-

Concrete septic tanks

-

In place concrete septic tank

-

Prefabricated concrete septic tank

-

Brick septic tanks (building materials)

-

Fiberglass septic tank

-

GRP septic tank

Installing Septic Tank - Running Septic Tank

Instructions for installing polyethylene septic tanks of Pars Ethylene Kish

In general, septic tanks are installed in the form of burial, land, and air. But given that in most cases the sewage inlet pipe is located in the basement of the septic tank, we have to install the septic tank as a burial type.

Septic tank manufacturing

Standard polyethylene septic tank manufacturer(polyethylene septic tank production): Pars Ethylene Kish, having the best septic tank production line (German manufacturing line, with experienced personnel and experts, is proud to be the largest tank septic tank manufacturer). This line of production of all stages is controlled and monitored by fully automated devices, the quality of the final product is acceptable to the extent of the company name and standards. It should be noted that this septic tank production line complies with the European day production standards.

Septic tank dimensions

The dimensions of the septic tank of the tanks manufactured by Pars Ethylene Kish are variable and can be produced in different volumes. This possibility is significant because septic tanks can not be less than 4.5 cubic meters, according to the formula, but it is only possible to demonstrate the maneuverability of the septic tank production line of Pars Ethylene Kish. For example, a 3.5-cubic meter septic tank with a diameter of 1.2 m and a length of 3.1 m can be produced and manufactured.

Calculating the septic tank capacity

Septic tanks are usually used for sanitary sewage. So here is the method of calculating the septic tank capacity for sanitary sewage. According to existing standards, septic tank capacity is considered equal to the amount of sewage production per day. Therefore, in order to determine the septic tank capacity required, it is necessary first to calculate the amount of sewage produced daily. The amount of sanitary waste usually depends on the number of people covered.

The following table shows the amount of wastewater produced per person in different conditions.

|

Usual amount |

Limit |

Unit |

Site |

No. |

|

L per day |

L per day |

|

120 |

80-150 |

Person |

Urban residential units |

1 |

|

150 |

120-200 |

Person |

Recreational villas |

2 |

|

50 |

30-60 |

8 hours personnel person |

Office buildings |

3 |

|

90 |

70-100 |

24 hours personnel person |

|

60 |

40-70 |

8 hours worker |

Factories and industrial workshops |

4 |

|

110 |

90-120 |

8 hours worker(bath available) |

|

60 |

40-80 |

8 hours personnel person |

Construction workshops |

5 |

|

100 |

80-120 |

24 hours personnel person |

Therefore, to calculate the septic tank capacity, the number of people per capita multiplied according to the table above. The resulting number is equal to the minimum capacity required for tank septic tanks. For further clarity, consider the following examples. Example 1: We want to calculate the septic tank capacity required for a sanitary wastewater from a production plant. The factory operates in two shifts, with a total of 150 workers and administrative personnel in the first shift, and in the second shift 80 workers.

Per capita of row 4 of the above table, per person or worker capita per shift is 50 liters. The total staffing is 230, so the required capacity of the product is multiplication of 230 to 50, which is equivalent to 11500 liters. Given the standard capacities in this example, it is recommended to use a septic tank of 12 cubic meters.

Maintenance of Septic Tank

To make the septic tank work better, the following points should be followed:

-

No specific time interval can be proposed for tank emptying, because it depends on the working conditions of the tank and the quantity of raw sewage. In general, if the capacity of the tank is accurately calculated and the spillage of waste into the sewage system can take place, this interval may last up to more than one year. No disinfectant should be disposed of during the treatment and operation of the tank. Because it eliminates bacteria.

-

Evacuation and cleaning of the tank can be done by the pump. Of course, it is possible to remove existing sewage and sludge by hand and even drainage from the tank.

-

When discharging, you should not pull out all the sludge materials, as this is unnecessary, and in addition, the presence of some sludge material is required from organic matter containing bacteria in the tank. Of course, fine materials and non-separable materials must be evacuated and removed.

.jpg)

.jpg)

.jpg)