New Generation of Corrugated Pipes

Parsethylene Kish corrugated Pipe Systems

All Parsethylene Kish corrugated Pipe Systems are produced with DROSSBACH’s own corrugated plastic pipe machines of the HD series.

The innovative approach, Corrugated Pipe Solutions offered by DROSSBACH,Parsethylene Kish is a contribution to solve the water problems caused by the fast increasing world population and the consequences of the global warming. Over the last decades DROSSBACH,Parsethylene Kish has gained experience in development and production of intelligent pipe systems and has thereby accumulated competence to present process optimised machines and pipe business orientated services. These are some of the established fundaments of the successful cooperation with partners worldwide.

-

Corrugated pipe production line

-

Corrugated pipe production line

-

Corrugated pipe production line

-

Corrugated pipe production line

-

Corrugated pipe production line

The consequences of the global warming, the further industrialisation, the strong increasing tourism and the progressive agglomeration are issues that require immediate efforts, while on the other hand these circumstances establish at the same

time excellent chances.

With Parsethylene Kish, the partner for sewage and rainwater drainage systems.

Lighter, more solid and truly higher quality !

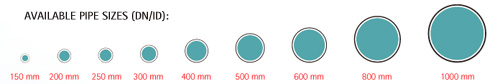

NOMINAL MEASUREMENTS

Measurements in mm ID range = interior measurements or nominal.

measurements: 150, 200, 250, 300, 400, 500, 600, 800, 1000

TECHNICAL HIGHLIGHTS:

-

Complete sewage and rainwater system with full fitting

-

and shaft program from ID 150 mm up to ID 1000 mm

-

Long-term tightness by SAFECONNEC

-

Optimised pipe design for highly secure and flexible pipes

-

Double wall pipe made of PP – high chemical resistance

-

Long life time of approximately 75 until 100 years

-

Resistant to high pressure jet cleaning systems (180 bar)

-

Excellent hydraulic properties due to KD = 0,25 mm

AREAS OF USE

-

Sewage and mixed water channels

-

Various special solutions for industry and business

STANDARDS

-

The material PP guarantees high modules of elasticity (Young’s) and ring stiffness of SN 8 following DIN EN ISO 9969

-

Profiled wall range 5 following DIN 16961 ≥ 31.5 kN/m2

-

Authorisation based on DIN 16961, DIN 19357 and DIN EN 13476

-

Suitable for all bedding materials following DIN EN 1610

-

Suitable for all normal pressure tests following DIN EN 1610

CHEMICAL RESISTANCE

-

The pipes and moulded parts as well as sealing elements have a chemical resistance between pH 2 (acid) and 12 (alkaline).

-

GIGAPIPE is resistant to all sewage and ground substances following DIN 1986.

THERMAL STRESS

-

GIGAPIPE pipes and moulded parts made of PP are used to channel sewage and rain water. The requirements of DIN EN 476 concerning the long-term temperature stress levels must be met: up to DN 150 +45°C and +35°C for larger measurements. The temperature ranges are between -25°C and +60°C.

Catalog of the New Generation Corrugated Pipe Pars Ethylene Kish - High Quality ⇒

The New Corrugated Pipe Specification and Catalog