polyethylene pipe temperature rating

Polyethylene pipes are widely used in various applications due to their durability, flexibility, and ease of installation. However, it is essential to know the temperature rating of polyethylene pipes to ensure that they can handle the operating temperatures of the application. In this article, we will discuss the importance of polyethylene pipe temperature rating, how to determine it, and its effects on the pipe's performance.

What is Polyethylene Pipe Temperature Rating?

Polyethylene pipe temperature rating is the maximum temperature that the pipe can handle without causing damage or failure. It is essential to know the temperature rating of the pipe as operating temperatures that exceed the rating can lead to cracking, brittleness, or melting of the pipe.

How to Determine Polyethylene Pipe Temperature Rating?

Polyethylene pipe temperature rating can be determined by referring to the manufacturer's specifications or consulting with a professional engineer. The manufacturer's specifications provide information on the pipe's material properties, including its melting point and heat deflection temperature. The heat deflection temperature is the temperature at which the pipe starts to deform under load, and it is a critical factor in determining the temperature rating of the pipe.

Effects of Temperature on Polyethylene Pipe Performance

The performance of polyethylene pipes is greatly affected by temperature. At low temperatures, polyethylene pipes become more rigid and brittle, making them more susceptible to cracking or breaking. At high temperatures, polyethylene pipes become soft and pliable, which can lead to deformation or melting of the pipe.

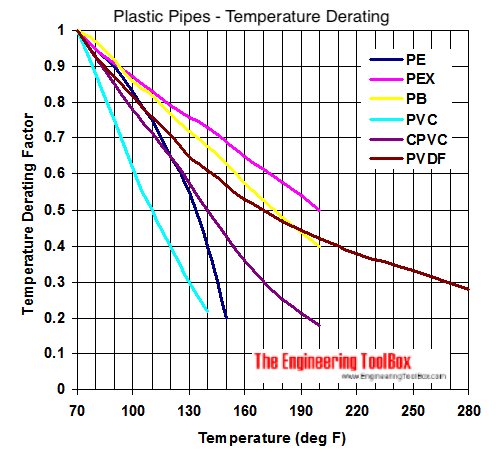

The temperature also affects the pressure rating of the pipe. As the temperature increases, the pressure rating of the pipe decreases. This is due to the reduction in the pipe's strength and stiffness at higher temperatures.

Polyethylene Pipe Applications and Temperature Rating

Polyethylene pipes are used in a wide range of applications, including water supply, gas distribution, irrigation, and industrial applications. Each application requires a specific temperature rating based on the operating conditions. For example, water supply pipes typically require a temperature rating of 60°C or higher, while gas distribution pipes require a temperature rating of 80°C or higher.

Polyethylene Pipe Grades and Temperature Rating

Polyethylene pipes are classified into different grades based on their density and molecular weight. The grades are designated by a code that indicates the density of the pipe. For example, PE80 has a density of 0.93 g/cm³, while PE100 has a density of 0.95 g/cm³. The temperature rating of the pipe is influenced by the grade of the pipe, with higher density pipes having a higher temperature rating.

Factors Affecting Polyethylene Pipe Temperature Rating

Several factors can affect the temperature rating of polyethylene pipes. These include the pipe's grade, wall thickness, operating pressure, and exposure to sunlight. Thicker-walled pipes can handle higher temperatures than thinner-walled pipes, and pipes with a higher operating pressure require a higher temperature rating.

Exposure to sunlight can also affect the temperature rating of polyethylene pipes. UV radiation can cause degradation of the pipe's material properties, leading to a reduction in the temperature rating of the pipe.

Conclusion

Polyethylene pipe temperature rating is an essential factor in determining the suitability of the pipe for a particular application. It is vital to know the temperature rating of the pipe to ensure that it can handle the operating temperatures of the application. By referring to the manufacturer's specifications or consulting with a professional engineer, the temperature rating of the pipe can be determined. Don't forget to check out the pe fittings catalogue for all your piping needs.