Polyethylene fittings

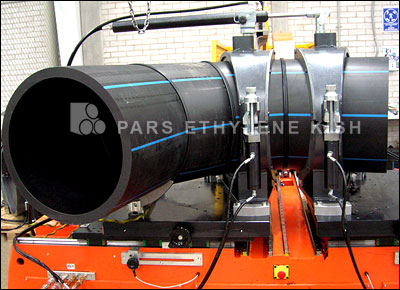

HDPE Fittings

Polyethylene pipelines require various PE fittings (HDPE Fitting) according to type of application.  PE pipes are used in sewage , water supply , fire systems , cable & gas covering, which each pipe fitting is suitably designed as per application demands. Electro fusion fittings are applied for gas supplies , but screw fittings are used in water supplies up to 10 atm pressure & for other projects polyethylene welded fittings are applied according to German DIN16963 . It should be noted that the domestic sewage systems do not follow the regulations above. See articles connection methods, for more information.

PE pipes are used in sewage , water supply , fire systems , cable & gas covering, which each pipe fitting is suitably designed as per application demands. Electro fusion fittings are applied for gas supplies , but screw fittings are used in water supplies up to 10 atm pressure & for other projects polyethylene welded fittings are applied according to German DIN16963 . It should be noted that the domestic sewage systems do not follow the regulations above. See articles connection methods, for more information.

PE fittings characteristics:

Joining PE pipes

Sewage Pipe Fittings

HDPE pipes are usually manufactured with two simple ends. Thus, in order to establish a connection between the two lengths, it is necessary to connect one simple end of a length to the simple end of the other with a fitting. The various methods used to connect HDPE pipes ( HDPE Pipe Fittings ), accessories and taps, are as follows:

1. Thermal butt (butt fusion)

2. Thermal bushing

3. Electrofusion

4. Flange

5. Extrusion

6. Bolting

7. Rubber gasket latching

The connection of polyethylene pipes should not be carried out inside the trench. The fairly large length of multiple lengths of pipes fused outside the trench will provide sufficient flexibility, with which it can be partly inserted into the trench, and keep the end of it to connect to the other lengths outside the trench. In order to perform the correct fusion, it is essential to observe the following principles and criteria:

• Pipes of different thicknesses should not be fused together.

• The flatted edges of the pipe ends should not be in contact with the hand after being chipped.

• Clean the cuts and particles from inside the pipe and onto the device.

• The device should not be wet, dirty and dusty.

• Do not expel pipes from the device before fully cooling.

• Use qualified people.

• As for any specific type of HDPE material, there is a certain range for the main parameters of fusion, including temperature, edge pressure and cooling time, before any PE fusion, the manufacturer should be consulted and the relevant personnel should be trained for implementation by the manufacturer or the manufacturer of the fusion device.

• If a connection between two types of HDPE pipes, pipes or related fittings is required, the fusion method must be sought from both manufacturers.( for more information resd HDPE Pipe Fittings )

• In the case of rainy weather, extreme winds and cold, avoid fusion. In case of necessity, the tent should be used, and in any case, the working environment temperature should not be below 0 C in any case.

In addition, the contractor must provide proper tools for performing the fusion. As a guide, at least the required equipment and machinery are as follows:

• A generator to provide the thermal energy for the iron plate, shredder and hydraulic pumps to provide the desired pressure

• The fusion machine should be equipped with appropriate clamps and timers.

• Clamps for fixing the two sides of the iro.

• Napkin to clean the iron plate

• Tools for cutting the extruded edges of the pipe from inside and outside

• Measurer the extruded part of the pipe

• Thermometer for measuring the surface temperature of the iron

• Cutting tool

• Thermometer for measuring air temperature

• Timer

Electrofusion is the most reliable method for joining PE pipes. In this connection, all accessories and fittings in PE pipe couplings, sockets or accessories are equipped with an electric heating coil. By heating coils, adjacent materials begin melting and by increasing the melting range and reaching the pipe wall, the outer surface of the pipe melts. Due the interaction between molecules, the pipe will join the socket.

Due to the limited production of PE pipes in terms of work pressure, diameter, accessories, connection type and production capacity, it is necessary to identify these constraints and adapt to the requirements of the design before making the pipe selection certainty.

For more information and download the catalogues visite HDPE Fittings Catalogue page

• Polyethylene Fitting Catalouge ( All type in Separate files - in 1 zip file )

• HDPE Fitting Cataloge ( All type in Single File - PDF )

• HDPE Screw Fitting Cataloge ( All type in Single File - PDF )

• HDPE Fitting Gallery