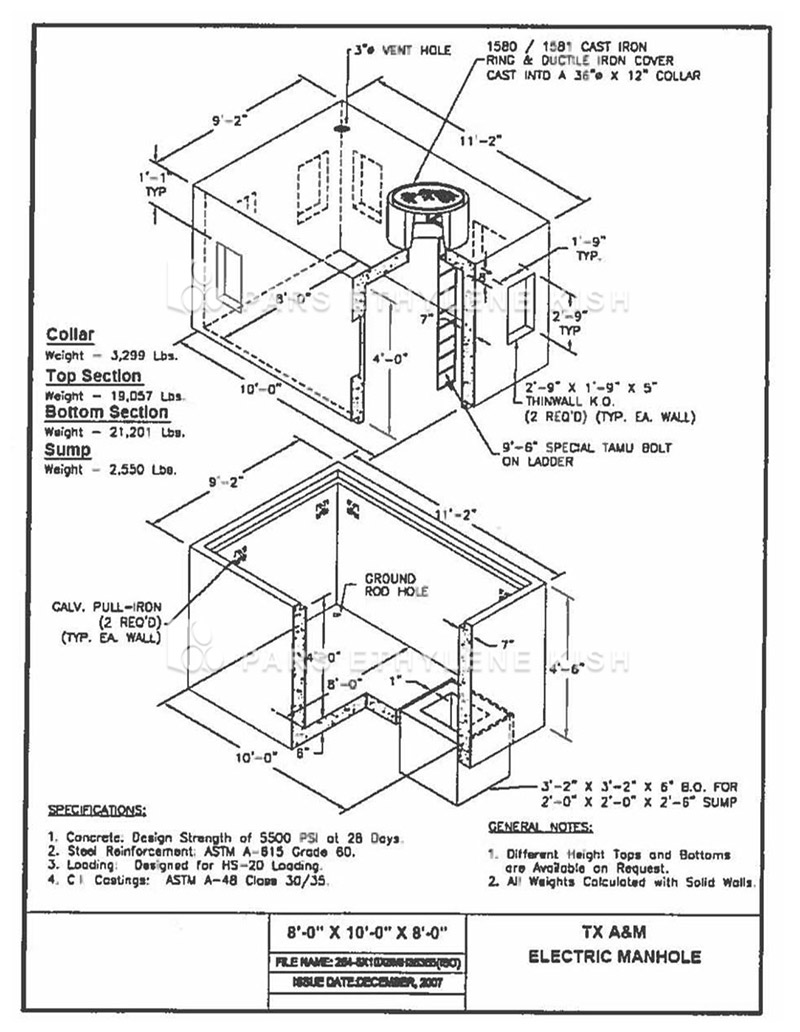

Electric Manhole

Polyethylene Manhole of Electrical

The electric manhole is usually used in pre-built mode, manholes installed locally are only used if required by the project. The electirc manhole is in a variety of types, including underground ductwork, the cables are inside it, and the electrician can enter the chamber and make the necessary changes and investigations. This box is also called work chamber or cable chamber.

All materials used in the electric manhole are supportive and protective of electrical wires and are connected at installation, and must comply with the standards for electric manholes.

Design standard of electric manhole

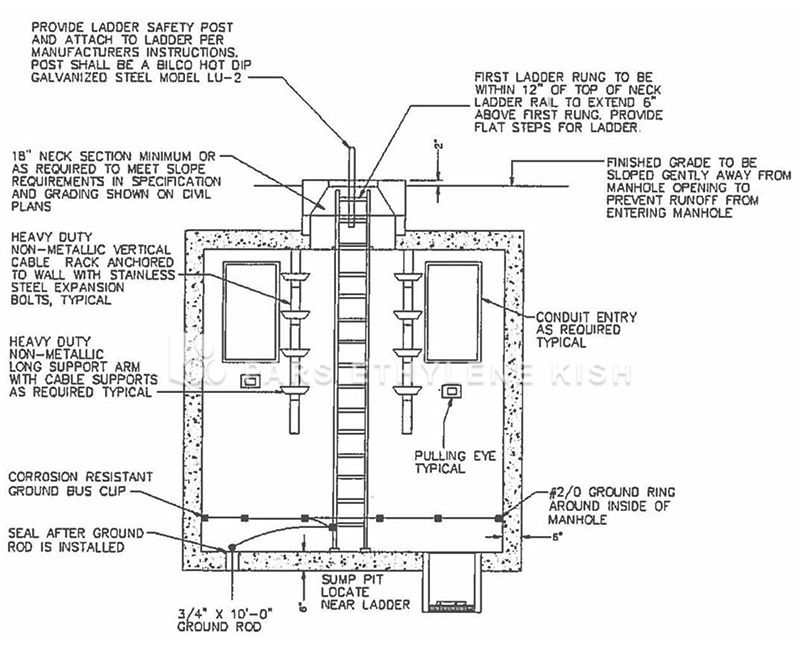

Installation instructions of electric manhole

-

1- Manhole should have minimum 42 holes.

-

2- The second ladder, which has a slider, should be in the middle of the manhole bo

-

3- The manhole flow test should be 600 A for the bodies and 200 A for the batches.

-

4- After the completion of the manhole project, the electrics have to be cleaned.

-

5- Sandblasting should be used to install manholes.

-

6- In manholes, a tight-fitted channel with a length of at least 10 ft is used, which has a galvanized bell at its end. Each manhole must have a canal that goes into and out of the manhole.

-

7- All cables must be aligned with the manhole wall.

-

8- All electrical manholes must be distinguished by the name 'ELECTRIC'.

-

9- All cables must be identified by their source name and type. Cable-related information should also be specified in blue and red colors to easily indetify their phases.

-

10- All keys should be down and can be managed from inside the manhole and turned on and off.

-

11- All empty ducts that enter the power manhole must be sealed.

-

12- All wires must be protected with flaps.

-

13- All internal manhole compartments must have the highest possible height.

-

14- All enclosures and their categories should be covered with glass fibers.

-

15- Packages should be 3 * 1.5 inches long.

-

16- The electric manhole door should be 4 degrees higher than the final size.

-

17- The ferrous metals used in the electric manhole must have a 48ASTM A standard in grade 30 and ranked.

Electric manhole diagrams

Electric manhole cables

-

1. All cables should be circled around the power manhole.

-

2. Each wall must have two enclosures to protect the cables.

-

3. Compression should also be done.

-

4. To prevent fire, fire extinguishers should be used.

Establishment of an electric manhole

-

1- All electrical manholes must have at least two 5-inch ground rails

-

2- All keys and electrical equipment used in manholes must be connected to the ground.

-

3- The ladder must also be connected to the ground.

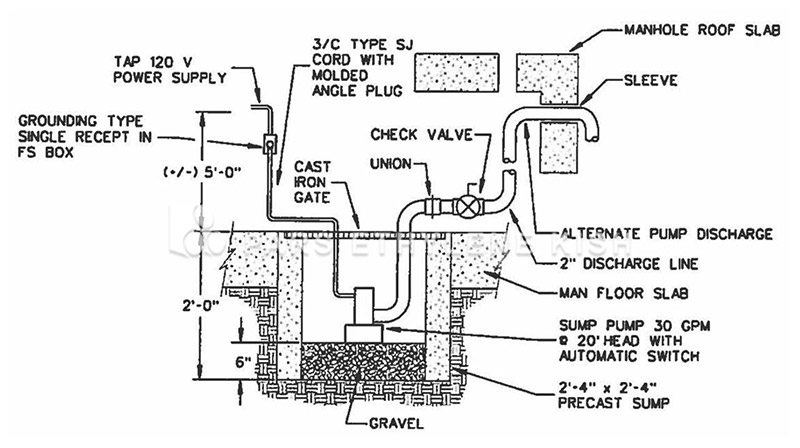

Valve pump

-

1. All electric manholes must have a valve pump.

-

2. Three tubes, with two PVC tubes, should be used for valve or pump pumps.

-

3. All manholes must have a sand dune with a valve having a minimum depth of 1 ft and a width and length of 18 * 18.

-

4. All manholes must have a valve pump.

-

5. The drainage pump of the PVC valve should be active in the manhole door and has a check function and can easily be cut off.

Advantages of Polyethylene electric Manhole

-

1. Low price

-

2. High speed run

-

3. 100 years Lifespan

-

4. Perfect sealing