Mechanical Fitting Repair

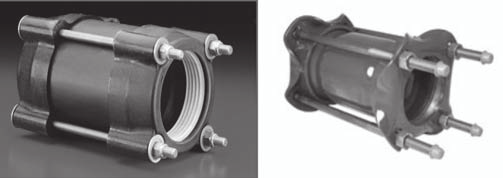

In some cases where the damage is slight but has severed the pipe, the line can be shut off and a small section of the pipe cut out to install a mechanical coupling in the damaged area . Contact the coupling manufacturer for the size

of damage that can be repaired. A certain amount of the piping system will need to be exposed to allow the pipe to be bent for the installation of the coupling.

Some couplings are self restrained and others are not. Some require a stainless steel stiffener inside the PE pipe and some do not.

For damage to small diameter water service lines (2 inches and smaller), mechanical compression fittings appropriate for PE pipe or tubing are commonly used for the repair. Water flow is stopped, generally using a pinch off tool, and the damaged area evaluated. If it is a small cut or hole, the polyethylene pipe can be cut in the damaged area and

a compression fitting installed between the polyethylene pipe ends. As required for larger pipe sizes, this method may require a certain amount of the piping system be exposed to allow the pipe to be bent for the installation of the coupling. If the damage is more extensive, a section of pe pipe is cut out and replaced with a replacement piece of pipe and two compression fittings.

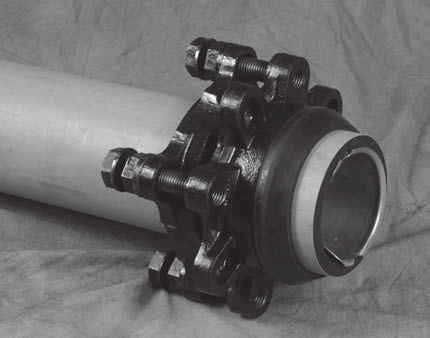

It is recommended that all couplings used with polyethylene should have a stiffener installed to increase the sealing capability of the coupling by minimizing the effects of creep and dimensional changes due to temperature variations. It is also recommended that, if the coupling does not provide its own restraint, then external restraints should be utilized on each side of the fitting to prevent pullout due to the thermal expansion or the Poisson effect of the polyethylene pipe. Mechanical fittings have different design advantages and accommodate different sizes. Contact the mechanical fitting manufacturer for more information. Several manufacturers make mechanical fittings specifically for use with PE, including Mueller, Elster Perfection, Victaulic, Dresser, JCM, Ford, Romac, Cascade Water Works and Smith-Blair.

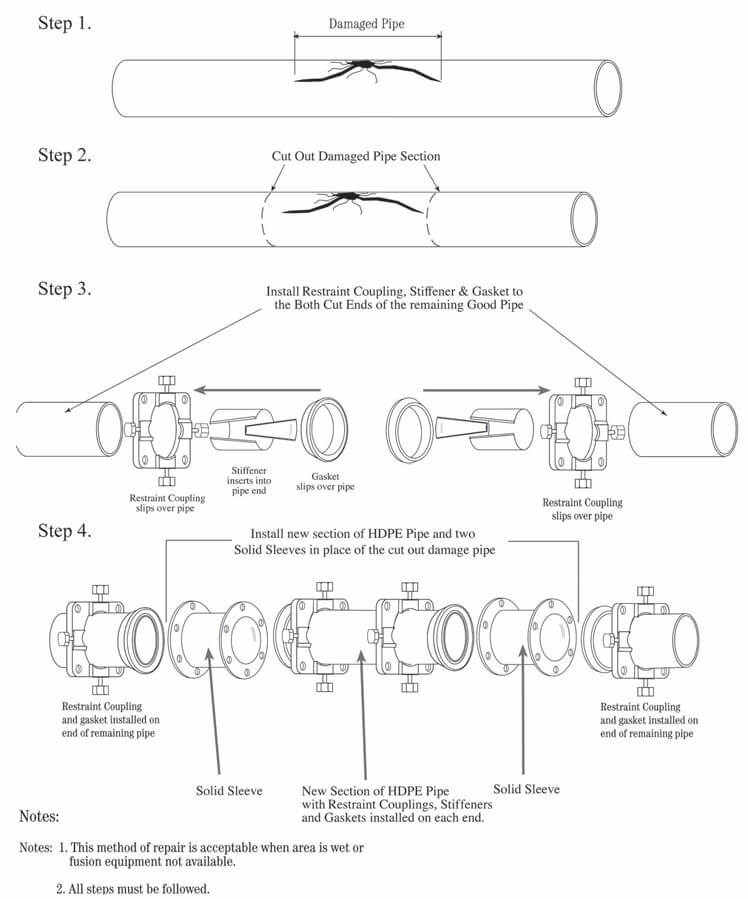

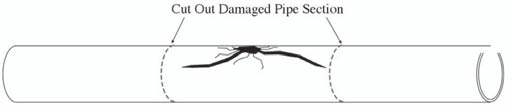

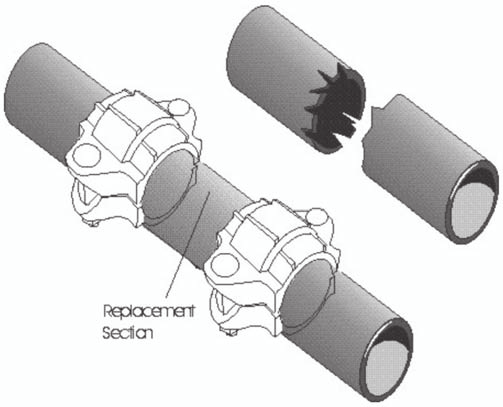

If the damage to the pipeline cannot be repaired with a single mechanical coupling as described above, two mechanical fittings can be used by cutting out the damaged pipe (Figure 8 & 9) and making up an assembly with two mechanical fittings and a properly sized and length of polyethylene pipe in the middle. Again, install per the fitting manufacturer’s instructions. (Figure 10) A repair to larger pipes requires joining devices for the size of pipe being repaired. However, the various types of joining devices discussed in this section may not be available for all pipe sizes. Contact the joining device manufacturer or supplier for availability and applicability with polyethylene pipe.

A saw is needed to cut out the damaged pipe and to cut the replacement section between the cut ends. A wrench is also needed to tighten the bolts. After the damaged section is examined, it can be removed. Damaged PE pipe is usually cut using a dry chain saw. Measure the distance between the cut pipe ends and cut an PE replacement section approximately ½-inch shorter than that length. Install the insert stiffeners in both ends of the existing PE pipes and in both ends of the replacement section.

Slide the couplings over the replacement section of the pipe and drop the assembly between two cut ends. Then slide the couplings between the replacement section and the cut ends and tighten the bolts using the manufacturer’s procedures.

Caution: Make sure to provide restraints or anchors for the PE pipe if the mechanical couplings are not self restrained. Failure to follow this procedure could result in the pipe pulling out of the coupling (see “Mechanical Restraint” section in this chapter).

As noted above, it is recommended that all PE pipe ends used with mechanical couplings have a stiffener installed to increase the sealing capability of the coupling by minimizing the effects of creep and dimensional changes due to temperature variations (see “Stiffener Installation Guidelines” section in this chapter).

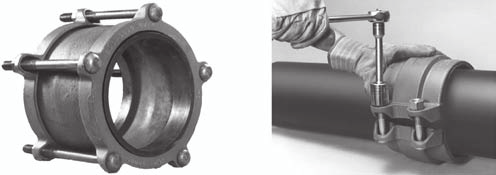

Repairs with Solid Sleeves

Repairs can be made using a mechanical joint (MJ) solid sleeve along with insert stiffeners, restraint device, gasket and tee bolts. A saw is needed to cut out the damaged pipe and to cut the replacement section of PE pipe. A wrench is also needed to tighten bolts. The pipe, gasket and solid sleeve must be cleaned before final tightening of the bolts.

The benefit of this repair method is that it can be made in a wet environment with no special equipment. This is basically the same repair method used for PVC and ductile iron pipe with the addition of insert stiffeners used with PE pipe. The parts are MJ sleeve or sleeves, glands, restraint ring, gasket, extra pipe if large area is damaged, gaskets and tee bolts.

After cleaning the contact surfaces, and installing a stiffener in existing PE pipe ends and in the ends of the replacement HPDE pipe section, slide the restraint ring and gland over pipe followed by a gasket as shown above. The drawing below shows a typical layout of parts needed to make a repair.

In a repair situation, the MJ sleeve is connected on both ends to PE pipe. The solid sleeve can make up small sections of pipe. If the damaged pipe is longer than the span of a single sleeve, two solid sleeves are used to replace damaged pipe.