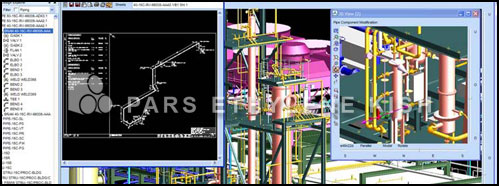

PDMS Catalogue

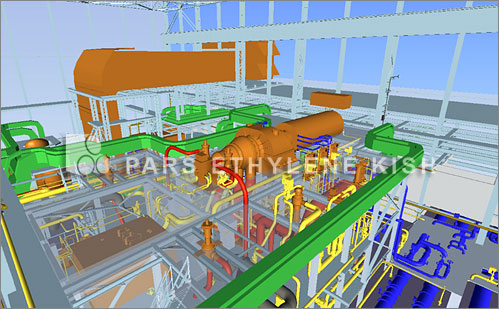

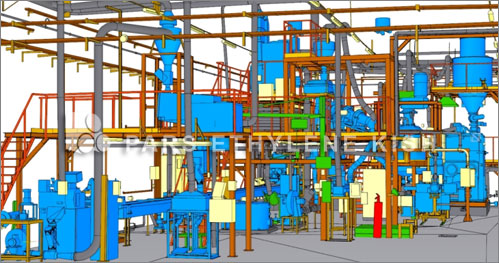

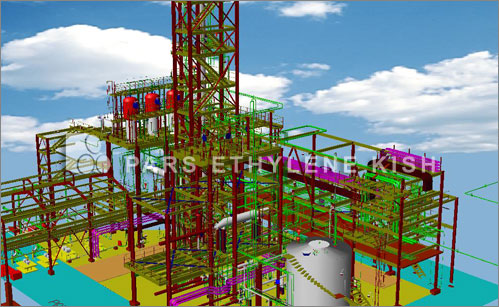

Simulated Pars Ethylene Kish Polyethylene Pipe Model by PDMS

The AVMS software of PDMS is one of the most efficient and most comprehensive softwares for modeling the oil, gas and petrochemical industries in the world, which is used in most countries as the first choice compared to similar software. As its name suggests, the program has the capability of designing and modeling on the one hand, and the ability to manage a site to the very top of the page. The high software capability in the modeling phase has led to the selection of the world's first software in the industry and the user is able to design and model a plant unit without the need for any other software.

Pars Ethylene Kish Co. has been working to standardize the implementation of polyethylene Pipe in projects in the country by making PDMS a catalog of polyethylene pipes and polyethylene joints. If you need complete information about this catalog, contact the engineering department of Pars Ethylene Kish.

Since this software is very robust and carefully designed in the database section, if a project with a proper structure and initially created by a person familiar with this software, there is no concern for the loss or breakdown of information.

Among the positive aspects of this software is the ability to match and send and receive files in order to coordinate with the most commonly used engineering science. If it has the capability to match the modeled files in the microstation and can be programmed with the Visual Basic language, it can output the types of reports in Excel format, Word, and also can output maps in PLT, DXF DWG format to AutoCAD.

In general, in order to familiarize you with the most important software environments and their efficiency, we give a brief overview of the environments.

For more information and Free Order of PDMS catalogue of HDPE Pipe contact us with mail : info@parsethylene-kish.com

DESIGN

In order to model a process unit from the beginning to the end with the most precise and complete details, in this section, various units of engineering units such as mechanics, structures, architecture, civil and electrical, etc., are modeled according to their task descriptions. One of the most important things that can be checked out in the Design module is the complete modeling of the Plant, checking the various components, viewing the latest user operations, getting reports from the model, and viewing the plant overview.

ADMIN

To define the project, create databases, define users, create a work area for each user, define a password, and manage the overall datas and software.

It is expected that an admin of a project will have sufficient control over all parts of pdms and will be able to solve the problems of other users.

PARAGON, SPECON to define the PIPING CLASSs of the project in the piping section and create catalogs for the sections, Piping Instrument, Structure and other sections are used. Generally, elements created by different units in the Design environment are initially introduced by experts in the Paragon or Specon environment, according to design standards and tables and project data.

ISODRAFT

It is used to prepare an isometric map that is derived from Piping output documents and extracted from the modeling phase of the project. Output maps are visible with AutoCAD software and are used in the site's implementation. This module defines the general settings for outputting maps and their size and management on how the output file is.

DRAFT

To provide different views and plan maps to position the equipment and pipes or other elements in the plant, it is a PDMS output document that can be converted and opened into AutoCAD files and used in the phase of building projects.

This module defines the general settings for how to output maps and their configuration and management on output files such as color, font size, storage location, data, measurements, creation of TAG on equipment and other settings.

SPOOLER

Isometric lines are used in the Shop and in the design phase of the project.

Generally, PDMS software can define a project at the highest possible level of project management, complete modeling of the process unit in all parts and output the file as a variety of reports, maps and 3D models.

PDMS Use Pars Ethylene Kish Polyethylene Pipes to design your projects and industrial sites free of charge.

For more information and Free Order of PDMS catalogue of HDPE Pipe contact us with mail : info@parsethylene-kish.com