|

Polyethylene Pipe Connection

The advantage of butt welding :

1. Its does not require special fitting for connection.

2. The butt welding machine are easy to supply in all corners of the world.

3. With butt welding ,some fitting like bends and t pieces can be produced at the site.

4. Butt welding can be applied for all diameter and for all pressure rating. (for best resultshe minimum wall thickness must be 3 mm)

5. Butt welding operation is very easy to learn and very practical.

Availability of more than one connection method.

Pe pipe have the several option for connection. The connection method is selected according to the place and condition where the pipe will operate.

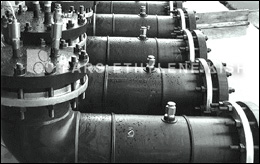

Butt welding method

This method of welding is the method most frequently used . For operating this welding ,an electric power source and butt welding machine is enough.

Electro fusion welding

This method is applied for ensuring the highest safety in the welding area. This welding is used especially for gas transmission pe pipes where any gas leakage can cause mortal disaster .a socket specially designed and produced for electro fusion welding and electro fusion welding machine is necessary for this welding .the cost of this weld is higher than butt welding. leakage can cause mortal disaster .a socket specially designed and produced for electro fusion welding and electro fusion welding machine is necessary for this welding .the cost of this weld is higher than butt welding.

Push-fitt socket connection

This systems is not a welding but instead a system of PE Pipe and muffle inserted into each other by pushing .this systems is preferable for the ones who like connection with o-ring .the superiority of this systems to the other o-ring systems is the usage of double o-ring which one of them ensuring the leak proof and the other prevents the movement of the pipe from its place in the socket.

Availability of connection at a place out of trench

Because of their elastic nature ,pe pipes can be connected at a place near the trench and then can be lay down into trench .during the lay down, the pipe connection points do not move or break. This method of making connection out of the trench can be applied to all pe pipes of every diameter

Case Studies...

• PE Industrial`s Experiences | Case Study »

• HDPE Performs best in Bow »

• Large scale pipe-bursting used in Windsor, Ontario »

• HDPE Pipe & HDD Solve Sewage Back-up Problem »

• Texas builds emergency HDPE water reuse pipeline »

• Use the PE 100 Supply pipes for the new construction of the BMW car factory in Leipzig »

• Hydroelectric Power Plant’s Steel Cooling Water Piping System Replaced with HDPE Pipe »

Valve | PEX pipe | Push fit system | Plastic pipe | HDPE pipe | Water pipe

UPVC pipe | Spiral pipe | Gas pipe | Underground pipe | Polyethylene pipe fitting | Pipe installation

|